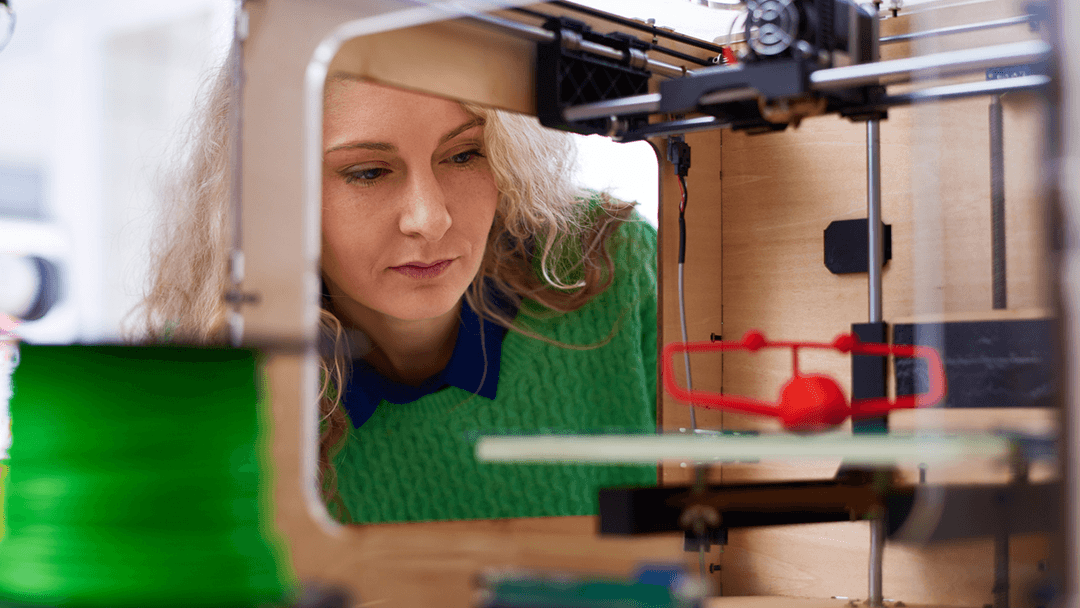

Ultrasonic Technology makes 3D printing even faster

3D Printing also known as Rapid Prototyping or Additive Manufacturing is a process taking a three-dimensional CAD design and building that component by depositing layers of material onto itself until the designed product is recreated in physical form. The layered material can be plastics such as ABS, nylon, etc. or metal depending on the style of printer.

Spotlight: HP1818 3D Printing Dyeing Tank

Omegasonics introduces the new HP1818 3D printing dyeing tank Looking to dye digitally manufactured parts built on Hewlett Packards’s Multi Jet Fusion 5200/ 4200 Series printers quickly and effectively? The twenty gallon HP1818 dyes parts faster, with more consistent results, uses significantly less dye material and with one-third less labor costs than other boiler dyeing methods. Unit is equipped with a high velocity circulation system to move heated material through printed part reaching even hard to reach areas with precision uniformity.

Precise and swift preparation is possible.

Stratasys Direct Manufacturing in Valencia, California, is one of the largest providers of additive manufacturing/3D printing, rapid prototyping, tooling and injection molding services in North America. A market projected to reach $13.4 billion by 2018. Even though it’s a market leader, it wasn’t always easy to keep up with client expectations. Printed items require precision cleaning and preparation. Stratasys used to either manually break or cut off support material, which was very labor intensive, or use heated circulating washers to melt it off, which required up to 24 hours for larger parts.

The company’s executive team went looking online for a faster solution and found Omegasonics, which happened to be in a nearby neighborhood. They went to see a demonstration for themselves and within a week ordered their first ultrasonic unit.

The company experienced an ROI in less than four months. Three full-time workers were reassigned from the cleaning process to other revenue-generating activities. Parts are getting to clients up to 24 hours faster than before.

It used to take a full day to manually remove support material from some 3D parts. Now we just put the parts into the ultrasonic cleaner and do something else while they’re being cleaned. After three hours, we have nice, clean parts.”

– Armen Boyajyan, Product Finishing Manager, of Stratasys Direct Manufacturing

The future of prototype manufacturing can get here even faster and easier.

- Gently removes support structure materials from ABS, Polycarbonate, Nylon 12 and PCABS, among others

- Thorough cleaning with even very intricate parts

- Less expensive than recirculating tank style washers

- Easy to use

- No setup or training

- No hand cleaning

- Reduced labor costs

Case Study

Learn how the largest dedicated provider of additive manufacturing/3D printing, rapid prototyping, tooling and injection molding services in U.S. made the switch to ultrasonic cleaning.