Knowledge Center

Featured Videos

Featured Case Studies

Featured Articles

Featured Blog Posts

Ultrasonic Cleaning 101

Learn about Ultrasonic Cleaning 101, ultrasonic transducers, cleaning solutions, maintenance, and more from Omegasonics, the most trusted name in industrial ultrasonic cleaners.

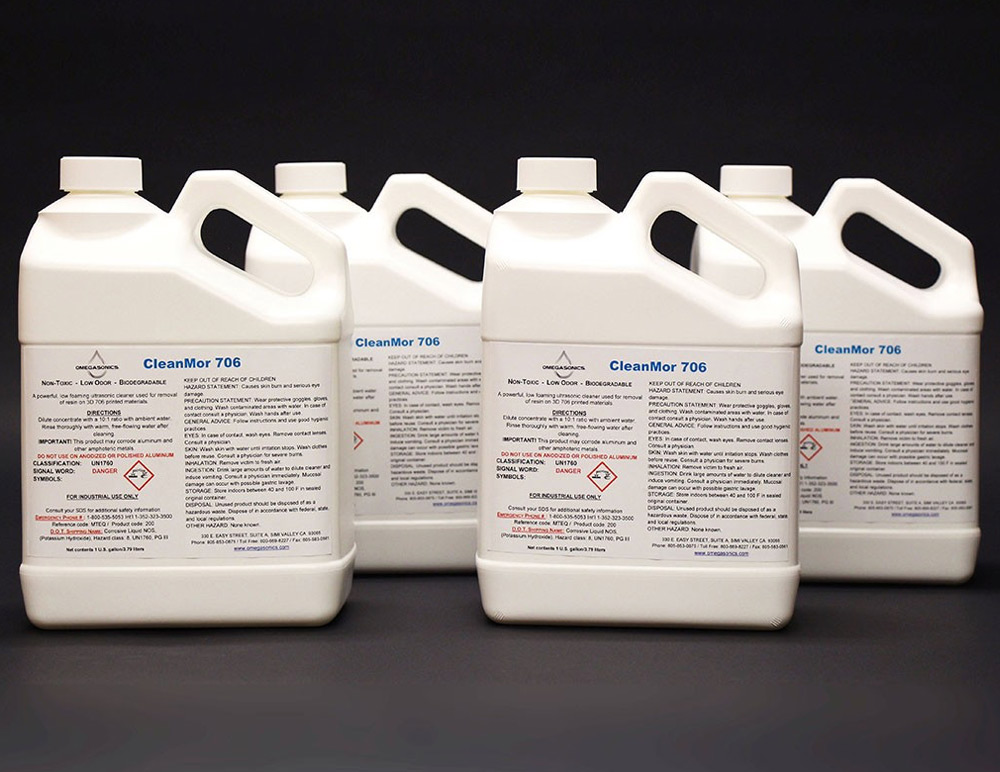

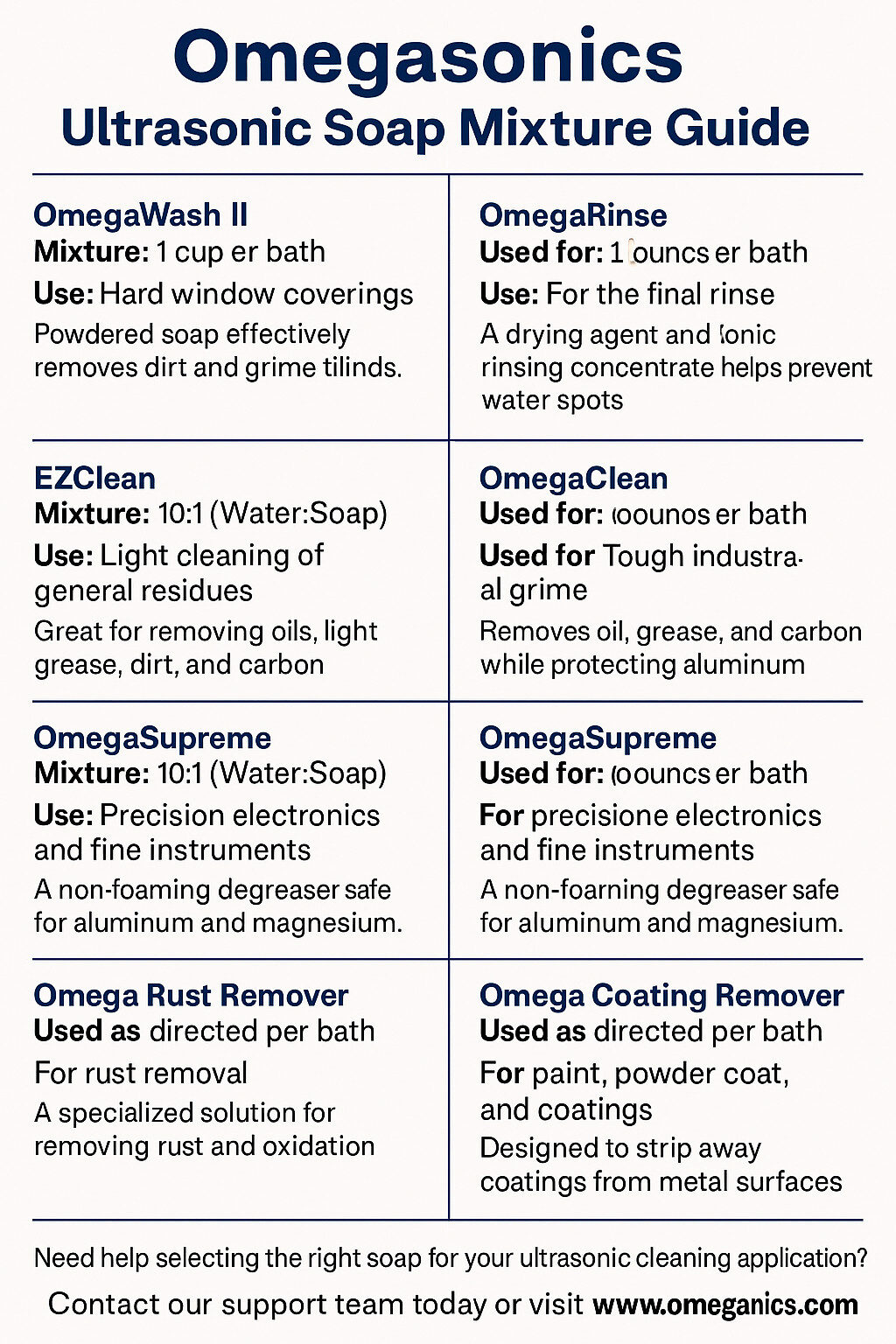

Ultrasonic Detergents 101

Learn about the many types of ultrasonic cleaning detergents and solutions. Finding the correct detergent is key to cleaning dirt and grime adequately without damaging parts.