Blog

Fast Food Cleaning

One double burger, chicken, nuggets, fries and a shake… sounds like a pretty typical fast food order. Sure, all that food will fill you up but is all the grease, cholesterol and trans-fat really worth putting into your body? Eating fast food is just like cleaning your industrial, automotive, or damaged restoration parts by traditional […]

Ultrasonic Moneyball

Recently released in theaters, Moneyball is the true story of Billy Beane, the general manager of the Oakland Athletics. The movie focuses on Beane’s attempt to assemble a competitive team for Oakland’s 2002 season, despite unfavorable finances and resources. What the trailer doesn’t mention is that the premise for Moneyball is actually partly based on […]

The Grass is Greener on the Other Side

“The grass isn’t always greener on the other side!” We’ve all heard this age-old phrase before, but what if the grass was actually greener on the other side? Well, my question is “what exactly is on the other side… and what makes it so green?” First of all, everybody using ultrasonic cleaning technology is already […]

Profitable Ultrasonic Cleaning shouldn’t be a Fantasy

After a long summer of lockout negotiations, it’s great that NFL football is back! Of course, that also means a return of fantasy football! Fans across the country spent hours studying up on their favorite players to draft the ultimate fantasy team. If you didn’t pick up Adrian Peterson, Percy Harvin, or Donovan McNabb, then […]

Ultrasonic Cleaning of Electronics

Did you know that there is a way to effectively clean sensitive items such as computers, televisions, stereo systems, and industrial electronics that have been damaged in a fire or flood? Frank Pedeflous, president of Omegasonics, gives a brief look at the restoration process of sensitive items such as electronics. More information can be found […]

Powerful Cleaning for Power Sports

Labor day has passed, but that doesn’t mean you can’t still enjoy a great day on the lake or in the mountains. Activities such as boating and jet skiing are a lot of fun for friends and family. But what isn’t fun is the teardown and maintenance process. If you own one of these types […]

Ultrasonic Cleaning’s Growing Contribution to Oil Exploration

High gas prices are often a touchy subject for most people, especially those who drive gas-guzzlers. Can you believe the price to fill up your car these days! A barrel of oil is over $90 this week. The gasoline used to fill up your car comes from thousands of oil rigs and offshore platforms. Primarily, […]

How to Choose the Right Contents Restoration Equipment

Are you looking to start or enhance a contents restoration division, but not quite sure where to begin? Frank Pedeflous, president of Omegasonics, gives recommendations about what equipment should be purchased to give your company a competitive advantage in the marketplace. Frank covers what kind of recovery rate could be expected for various items of […]

Omegasonics Announces New and Improved Site

We proud to announce that the newly redesigned website for Omegasonics went live yesterday! After a five-month process, we are very excited with the way everything turned out. Our goal with the new site was to extend the functionality of the navigation for the user. It features modified content, streaming videos, new pictures and incorporates […]

Restoration Professionals: Flood Damage Heroes

Winds reaching 115 miles swarmed the East Coast last weekend in what was known as Hurricane Irene. With much fortune, the damage was far less severe than what was initially expected. With a storm this size, the flooding of homes and business is typically one of the lingering effects. In combination with insurance companies, restoration […]

A Safer Way to Handle Industrial Waste Disposal

You wash your hands with soap and water, so why wouldn’t you wash your industrial parts in the same way? The world is turning “green” and more businesses than ever are choosing safe and eco friendly methods to clean their industrial parts and machinery. One reason ultrasonic technology is superior to other forms of cleaning […]

Ultrasonic Cleaning Takes Off in the Aerospace Industry

Halfway between Detroit and Kalamazoo, on I-94 in Jackson, is the Eaton Aerospace facility. Founded in 1940, the onset of WWII helped establish Eaton’s preeminence in fluid power technology, as its Aeroquip brand components went into America’s military aircraft. Today, Eaton Aerospace continues the tradition by creating products that convey air, oil, water and Freon […]

How to Establish a First Class Restoration Division

Are you in need of setting up or improving your fire and water restoration division? Your company can specialize in the cleanup and restoration of property after a situation involving fire damage, smoke damage, or water damage. In this video, we give a few helpful steps that you and your company can take to maximize […]

Why Industries have Increased their use of Ultrasonic Cleaning

In the 1980’s, the U.S. government began to crack down on un-safe industrial cleaning chemicals, and created the need for new, safer, greener, water-based cleaning solutions: one of the key alternatives being ultrasonic cleaning technology. As government regulations on toxic chemicals used in the workforce were tightened, industrial companies were frantically searching for newer and […]

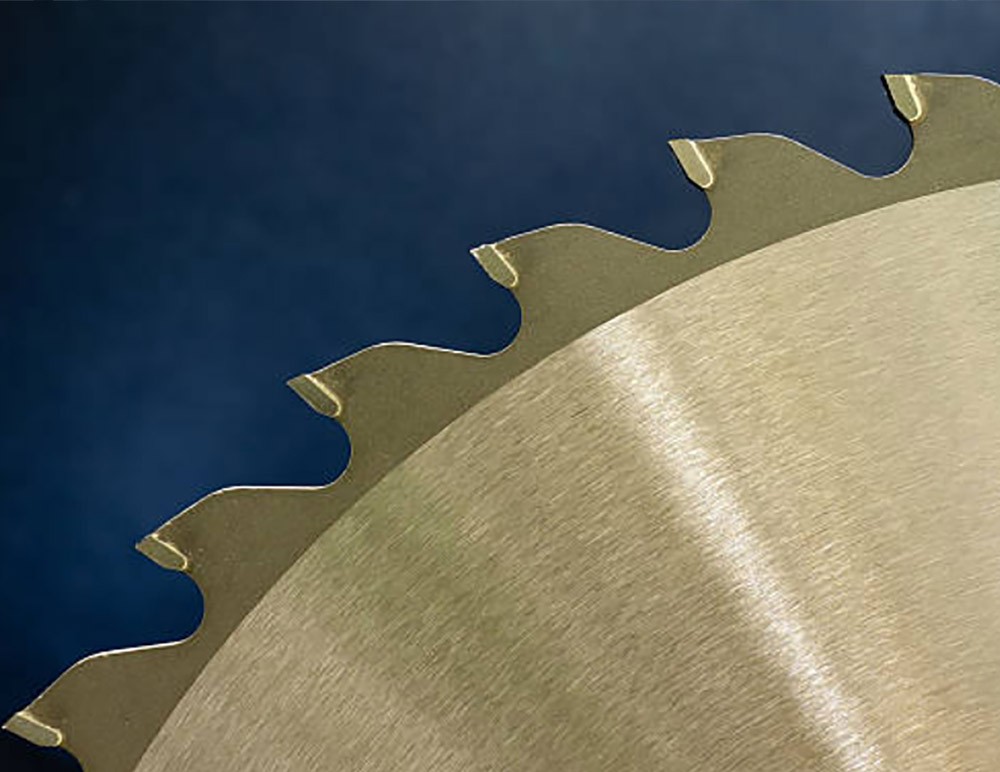

Cutting Saw Blade Cleaning Costs in Half

Imagine cleaning a saw blade with just rags and some cleaning chemicals. Do you really want anyone’s fingers near those sharp metal tips when they can’t see the edges? With ultrasonic technology you can eliminate the nervousness surrounding cleaning saw blades. After rigorous use in the field, cutting tips on saw edge blades edges become […]

Ultrasonic Cleaning – “Instrumental” for Success in Music

If you are in the music industry, whether as a hobbyist or as a professional, you probably have plenty of experience trying to clean musical instruments. As you know, it’s a lot more fun to play an instrument than it is to clean one! I don’t want to start off this blog on the wrong […]

Ultrasonic Gun Cleaning

Jim Green of Omegasonics demonstrates how gun cleaning can be done effectively, efficiently, and safely using an ultrasonic cleaner. The best way to restore a case back to its original perfection is with ultrasound and water based soaps. This unique technology is capable of cleaning specialized gun parts in a fraction of the time, reaches […]

Increase Musical Instrument Cleaning Profits 300%

Rick of Arrowhead Band Music says that he and his brass tech love the 59-gallon Music Pro Ultrasonic Cleaner. He says that it cleans his instruments much faster, and he can sleep at night not having to worry about OSHA regulators. One major benefit of ultrasonic cleaning is the ability to clean small, intricate pieces […]